- Home

- G‑Floor® Outdoor & Marine Flooring – Simplicity Collection

- Outdoor & Marine Vinyl Flooring Simplicity

Outdoor & Marine Vinyl Flooring Simplicity

SKU:21-48812-05

Low stock: 8 left

Why You'll Love It

- Ultra-durable polyvinyl ensures your flooring can withstand extreme weather conditions and heavy foot traffic, making it perfect for outdoor and marine environments.

- Seamless moisture protection resists wood rot, mold, and mildew, providing long-lasting durability and peace of mind.

- Marine-grade top coat with UV-inhibitor maintains vibrant colors and images, while its anti-microbial qualities prevent mold growth.

- Easy DIY installation with trim-to-fit capability and cushioned backing allows for quick and hassle-free setup.

- Slip-resistant and flame retardant properties enhance safety, ensuring a secure and worry-free experience on the water.

- What's in the Box: G‑Floor® Outdoor & Marine Simplicity Poplin Collection vinyl flooring.

- Pattern: Non-woven, seamless design with a leather-like Levant™ surface.

- Material: 100% polyvinyl, 90 mil thick with a 50 mil wear layer and marine-grade topcoat.

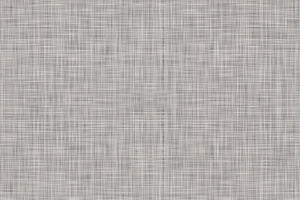

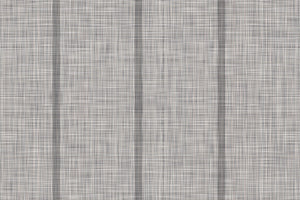

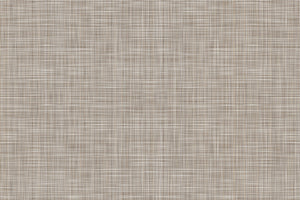

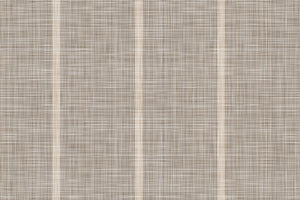

- Color Options: Five colorways including Brentwood Grey, Brentwood Tan, Castle, Castle Dark Stripe, Sand and Sand Light Stripe.

- Additional Features: Waterproof, UV-stable, slip- and odor-resistant, easy DIY installation, and manufactured in the USA with a 5-year Limited Warranty.

- Boats: Ideal for enhancing the aesthetic and durability of boat flooring with its marine-grade topcoat and slip-resistant features.

- Decks: Provides a seamless and moisture-resistant surface, perfect for outdoor decks exposed to weather conditions.

- Docks: Offers a durable and UV-stable solution for dock flooring, preventing wood rot and mold growth.

- Patios: Adds a sophisticated look to patios with its leather-like Levant™ surface and easy DIY installation.

- Lanais: Ensures a stylish and safe flooring option for lanais, with its flame retardant and odor-resistant properties.

- Prepare the Surface: Ensure the area where the vinyl flooring will be installed is clean, dry, and free of debris. Remove any existing flooring if necessary.

- Measure and Trim: Measure the area to be covered and trim the vinyl flooring to fit using a utility knife. Leave a small gap around the edges for expansion.

- Apply Adhesive: Roll out the vinyl flooring and apply a marine-grade adhesive to the back of the flooring or directly onto the surface, following the adhesive manufacturer's instructions.

- Install the Flooring: Carefully position the vinyl flooring onto the adhesive, starting from one end and working your way to the other. Press down firmly to ensure a good bond.

- Finish and Secure: Trim any excess material and secure the edges with a roller or by applying additional adhesive if needed. Allow the adhesive to cure as per the manufacturer's instructions before using the area.

G‑Floor® Outdoor & Marine Simplicity Poplin Collection is seamless, 100% polyvinyl, 90 mil thick with a durable 50 mil wear layer. The non-woven marine flooring is complete with a marine grade topcoat. DIY rollout flooring is waterproof, easy care, UV-stable, slip- and odor-resistant. The Poplin Collection comes in nine colorways- Castle, Castle Dark Stripe, Castle Light Stripe, Sand, Sand Dark Stripe, Sand Light Stripe, Ray, Ray Dark Stripe, and Ray Light Stripe.

Bring aboard soft, subtle, neutral tones to match any upholstery color combination. With three color options and three pattern options, your boat will feel sophisticated and custom. The Simplicity Poplin collection offers the weave without the snag. The G‑Floor® Outdoor & Marine Simplicity Poplin Collection is non-woven and ideal for boats, decks, dock, patio, and lanai flooring! The leather-like Levant™ surface enhances the beauty of any watercraft. The Simplicity Poplin Collection entwines strands of light and natural colors to duplicate the appearance of fine woven cloth. This flooring provides effortless style, versatility, and performance on the water, along with a list of other advantages:

- Ultra-durable polyvinyl – handles extreme weather conditions and heavy foot traffic

- Non-woven material – won’t snag, dent, crack, flake or peel

- Seamless with superb moisture protection – resists wood rot, mold and mildew

- Sharp, high-quality images are printed underneath the vinyl, not on top or in between, and protected by an industry-leading wear layer so they won’t fade or wear off

- Marine-grade top coat – UV-inhibitor for long-term color and image retention; anti-microbial qualities so no mold grows between fibers/weaves; no-blush surface won’t leave marks from wet towels, bathing suits, cooler, life jackets, etc.

- DIY installation, trim to fit, and cushioned spun bound backing for quick grabbing of glue

- Easy to clean, non-porous surface resists oils, gas and marine chemicals

- Odor- and stain-resistant

- Slip-resistant and flame retardant for safety

- Manufactured in the USA

- 5-year Limited Warranty, 3-year UV exposure

Shop the Collection

G-Floor

Outdoor & Marine Vinyl Samples

G-Floor

Outdoor & Marine Vinyl Flooring Premier Collection

G-Floor

Outdoor & Marine Vinyl Flooring Simplicity

Why G-Floor® Flooring

Quality You Can Depend On

It’s more than just a surface to walk on, it’s a testament to the dedication of those who innovate and craft quality G-Floor® Flooring

-

Built to Last

Built to LastIndustry-leading durability with premium vinyl flooring that stands up to heavy use—indoors or out.

-

DIY-Friendly Installation

DIY-Friendly InstallationInstall your garage flooring, coin floor, or pet flooring in under an hour—just roll out, trim, and you're done.

-

Low-Maintenance Durability

Low-Maintenance DurabilityEngineered to handle tough conditions while staying easy to clean and looking great.

-

Proudly Made in the USA

Proudly Made in the USAManufactured for over 20 years in America’s heartland using quality materials and unmatched craftsmanship.

⚠ WARNING: Our products can expose you to Antimony Oxide (Antimony Trioxide), Diisononyl Phthalate (DINP), or Di(2-ethylhexyl) Phthalate (DEHP) a chemical known to the State of California to cause cancer.

For more information, visit www.P65Warnings.ca.gov.